Swagelok Orbital Welding Services

According to the American Welding Society (AWS), over 20% of welding professionals are approaching retirement. In addition, they project there will be an average of 80,000 welding jobs to be filled annually between 2025 and 2029.

Undoubtedly, it will become even more difficult to find welders in the near future. Eliminate this concern by bringing your weld projects to us.

Let Us Weld it

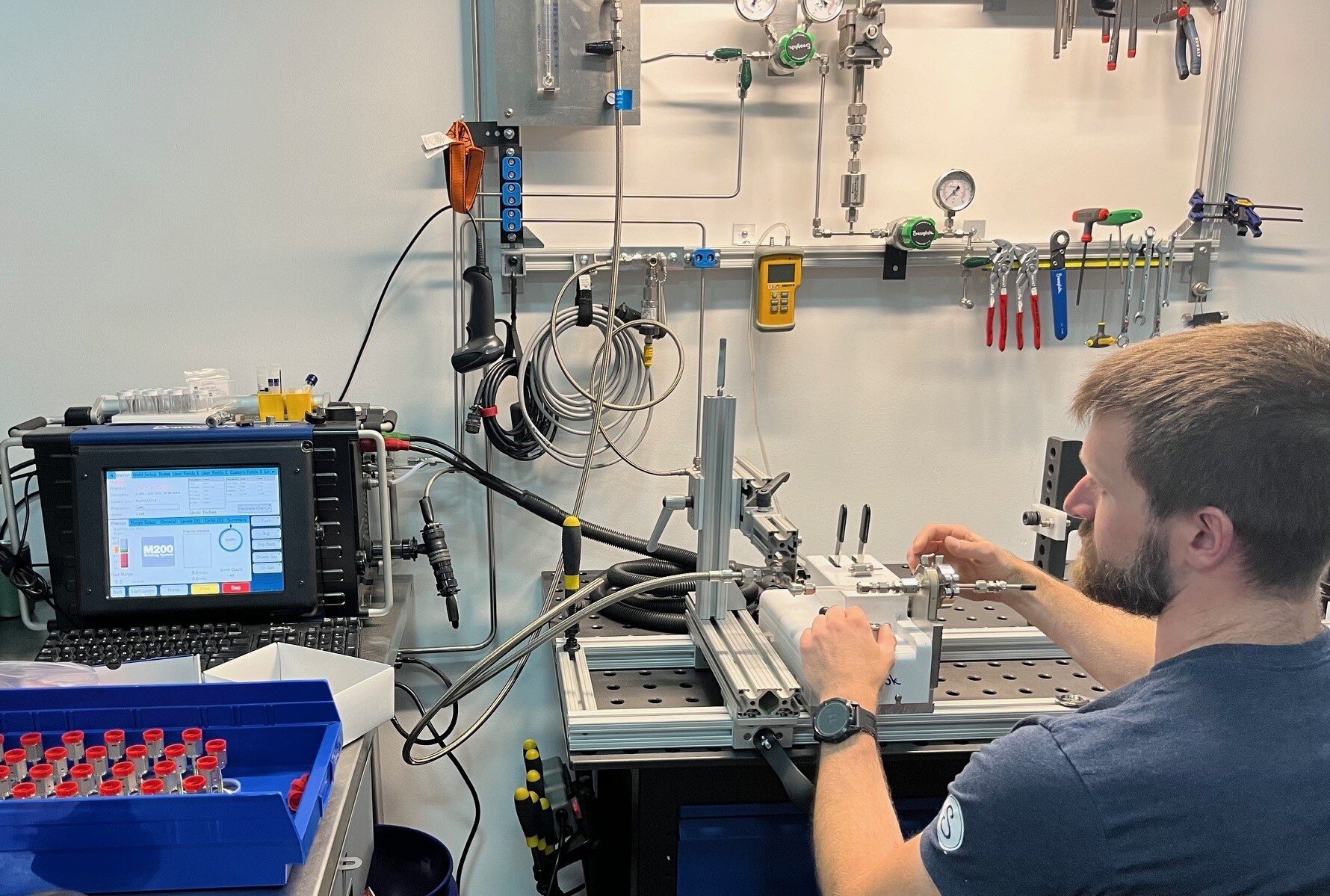

At Swagelok Western NY we developed an orbital weld program years ago to provide an additional level of support to our customers. Our on staff, factory-trained and ASME IX certified weld operators and examiners have welded stainless steel tubing systems for an array of applications across industries - from simple weldments to complicated spool pieces, general industrial to sanitary and high purity.

- Our orbital weld operators are fluid system experts

- We maintain rigorous standards for concavity and convexity tolerances

- Helium leak testing is conducted to ensure the safety and quality of every weld assembly

- No scrap or rework for you to worry about - we deliver a finished piece that you can install directly into your system

- Material expertise – Swagelok products contain a consistent balance of chromium, nickel and sulphur that assures the quality and integrity of the weld, especially important for high-purity applications.

Continual Investment

Our operators perform thousands of welds yearly, providing much needed manpower to companies that find themselves short-handed. To that end, we continue to make investments to increase the proficiency of our associates and the quality of our welds.

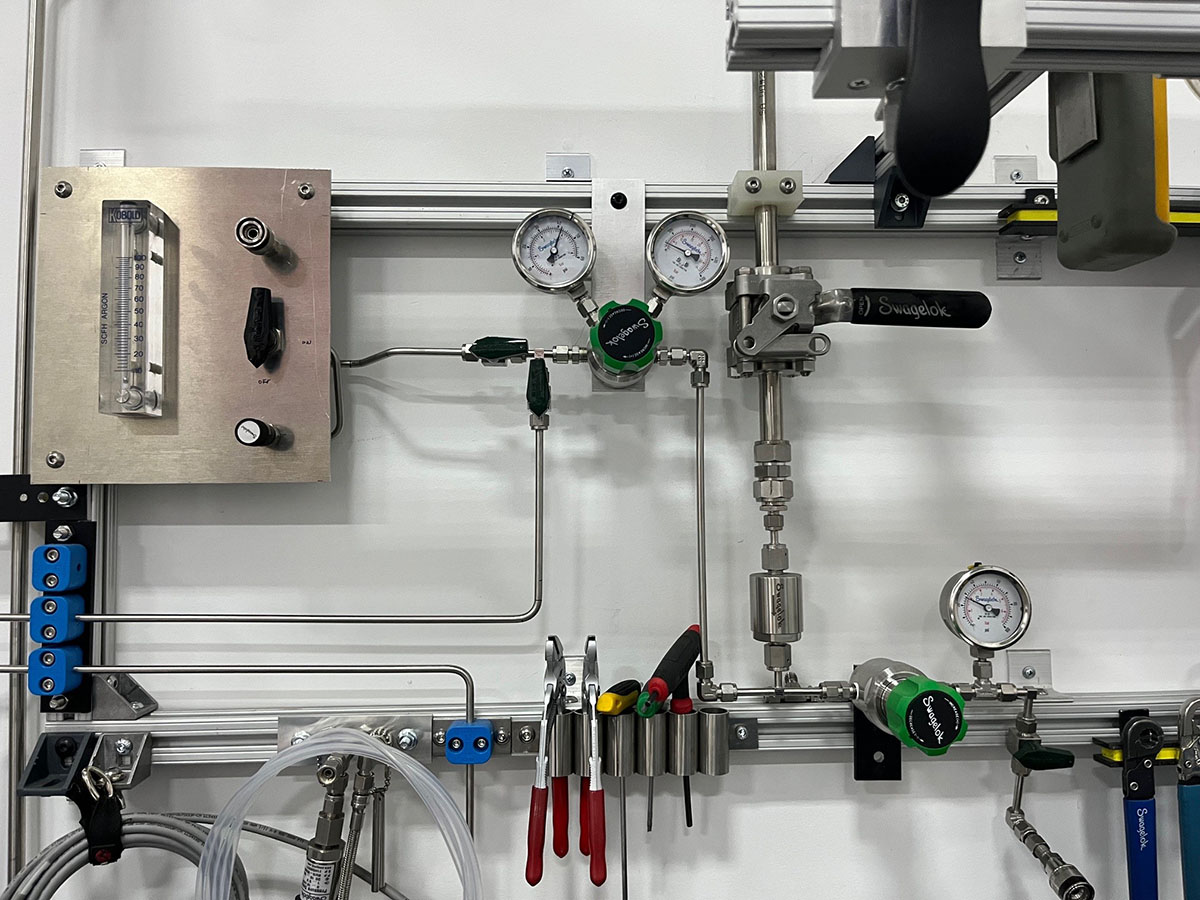

Argon Purge System

We installed a central argon gas system to yield greater efficiencies of scale and higher quality, cleaner welds.

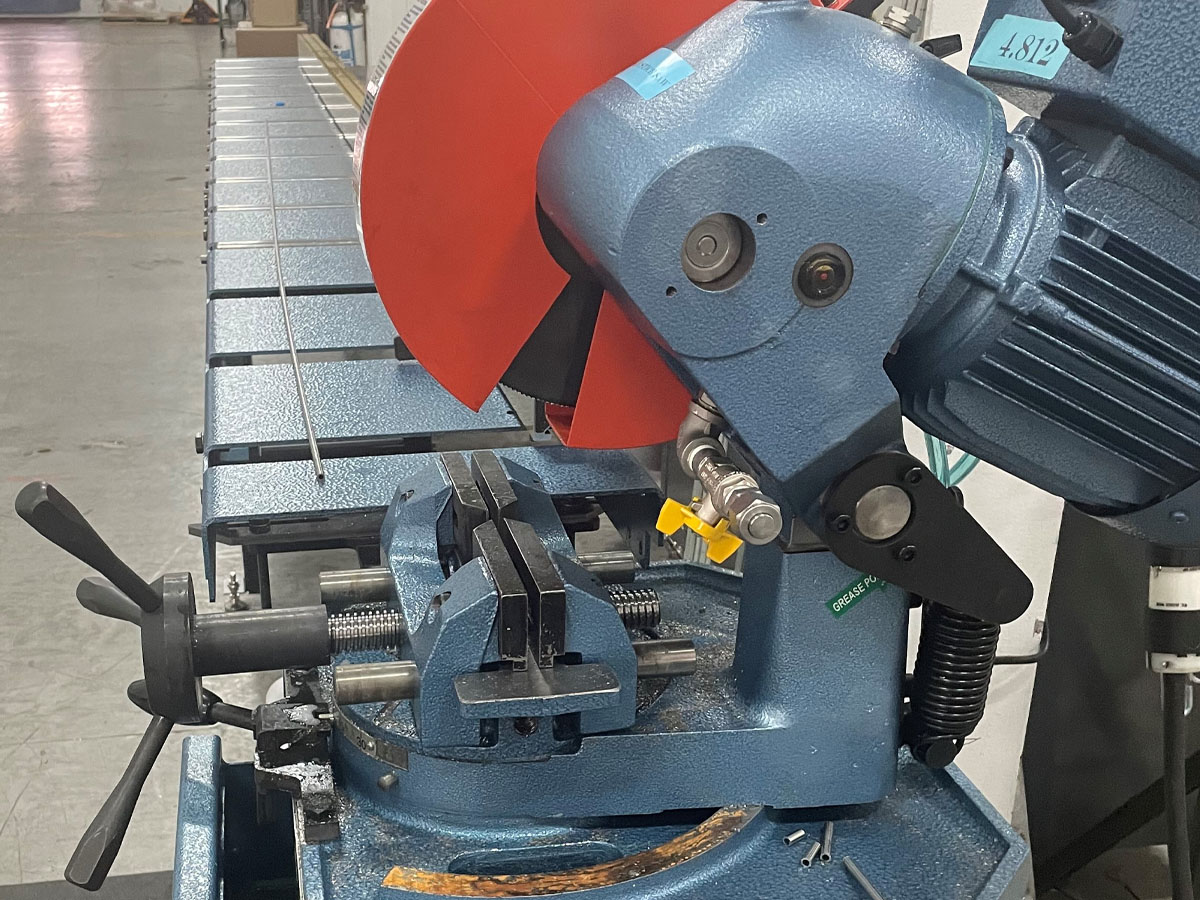

Scotchman Circular Cold Saw

Full automation capability to produce precise, repeatable stainless steel tube cuts.

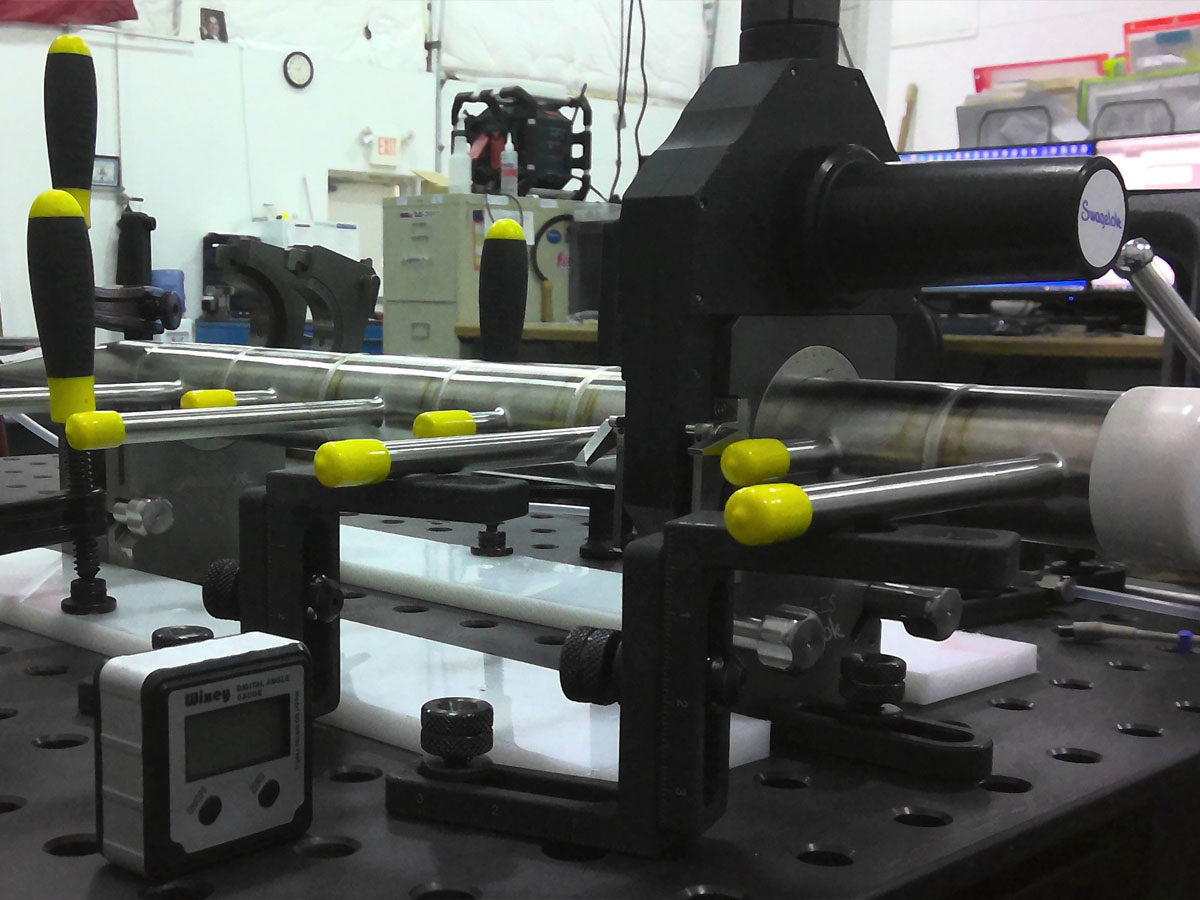

Precision Fixtures

Reduces weld variability; streamlines set up and inspection

Digital Industrial Endoscope

Enables inspection of tubing and provides visible proof of internal weld quality.

Clean Room

Enables us to perform welds for ultra high purity applications.

Local Technical Support

Whether you are purchasing or renting our weld equipment, you have access to our local subject matter experts for technical support and training to assure maximum productivity.

- On-site demonstrations and training for your team

- Everything but the Gas - Units delivered with everything needed to weld; complete and ready to go (gas supply not provided)

- Fast turnaround of equipment repairs and servicing

- Emergency equipment substitution

Calibration

We are certified locally to calibrate welders. We provide free pickup and delivery between our three local offices in Rochester, Buffalo and Syracuse.

- M200 power supply will be cleaned, calibrated and tested. This also includes software upgrade.

- A certificate of calibration will be provided that includes results of current, voltage, and weld head speed.

Rental Program

- Units are delivered complete

- Training and support is provided throughout your rental period

Calibration

Local Calibration:

- Calibration at our Rochester Facility

- Local pick-up and delivery

- 3 to 5 days turnaround time

Swagelok Factory Calibration:

- Located in Solon, Ohio

- Multifaceted inspection by a Factory Technician

- 3 to 5 week turnaround time

Training

Connect With Our Experienced Team

Our fluid system experts assess your system performance to help deliver an optimized solution and engaging customer experience.