Orbital Welding

Orbital welding is a semi-automated welding process that uses no additional weld material and instead fuses two products together. This process is ideal for critical applications requiring weld integrity and high purity.

Key Benefits of orbital welding

Whether you have a preliminary drawing or just an idea, it’s not too early to consult with our fluid system experts for our support:

- Repeatable, accurate welds

- High volume weld capacity

- 100% penetration of weld

- Suitable for nearly all industry applications

- No additional weld material is used making it ideal for critical applications requiring weld integrity and high purity

- Real-time monitoring and data recording

- Cost effective and reliable gas tungsten arc welds

- Lightweight, portable power supply

- Selection of weld heads

- Variety of tools and accessories

Swagelok Orbital Welding System

The Swagelok M200 Orbital Welding System combines precision, control, and touchscreen ease-of-use to help weld technicians create perfect welds with consistent bead profiles and full penetration. Its semi-automated GTAW process and versatile modular fixturing accommodate a wide range of tubing, pipe, and component combinations. Real-time monitoring and recording streamline documentation for industry compliance.

Our experienced team provides quick turnaround of high-quality welds. Contact us to support your next weld project.

Equipment We Offer for Purchase or Rental

For use with our complete line of Swagelok tubing, weld fittings and valves:

- M200 Orbital Power Supplies

- Weld Heads ranging from micro to 40 head (for tubing with outside diameters of 1/16" to 4")

- Wide range of collet sizes for all weld heads

- Facing Tools and their respective collets

- Tube Saw

Purge Kits and Systems

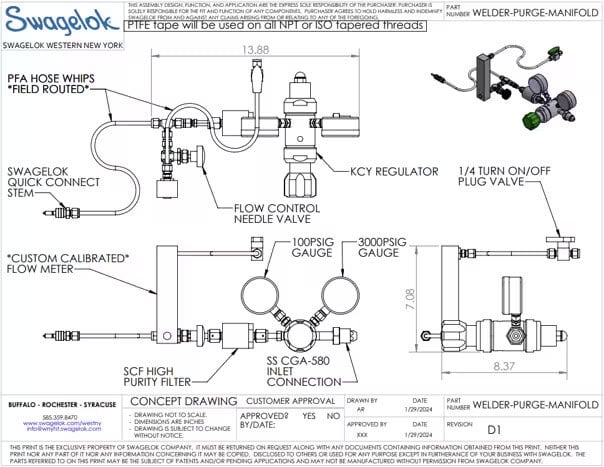

Gas purge is a critical process for welding, but one where vital equipment is often overlooked. Swagelok WNY offers pre-built gas purge package accessories that ensure your weld operators have everything they need on Day 1 of the project.

In addition to UHP purge kits, Swagelok WNY provides individual UHP purge equipment and complete gas delivery systems:

- Distribution Manifold

- Purge Panel

- Purge Tree

- Gas Stick

- Purge Stick

Each of these pieces come in standardized designs, with BOMs and part numbers for straightforward ordering, but are easily customizable to the demands of your project.

Local, in-house Swagelok WNY engineers and certified assembly technicians build and test each piece ensuring they are ready for installation upon delivery to the job site. All assemblies receive the same Swagelok Limited Lifetime Warranty as our components.

Orbital Welding Training

Associate Training

Enable your associates to safely and effectively operate an orbital welder through our 1-day, on-site Orbital Welding Training. Our trainers will provide theory and hands-on practical training customized to meet the needs of your project or business.

Student Training

The 1-day Orbital Welding Training is a perfect way to introduce your students to the automated welding system. We have conducted Orbital Welding trainings for both BOCES and University programs. Watch the above news video from our training day with the Tompkins-Seneca-Tioga BOCES welding program at the Cornell NanoScale Facility.

Topics

The 1-day Orbital Welding Training program is open to welders of all experience levels and is designed to help operators:

- Gain an understanding of orbital welding principles

- Understand setup and operation of the Swagelok M200 Orbital Welding System

- Appreciate the importance of gases (shielding and purging) in the weld process

- Troubleshoot frequently encountered welding problems

- Avoid operational issues through hands-on experience

Additionally, Swagelok offers a 5-day training program at the factory in Solon, Ohio that will enable trainees to test for ASME Section IX qualification.

Rental Program

- Units are delivered complete

- Training and support is provided throughout your rental period

Calibration

Local Calibration:

- Calibration at our Rochester Facility

- Local pick-up and delivery

- 3 to 5 days turnaround time

Swagelok Factory Calibration:

- Located in Solon, Ohio

- Multifaceted inspection by a Factory Technician

- 3 to 5 week turnaround time

Training

Connect With Our Experienced Team

Our fluid system experts assess your system performance to help deliver an optimized solution and engaging customer experience.